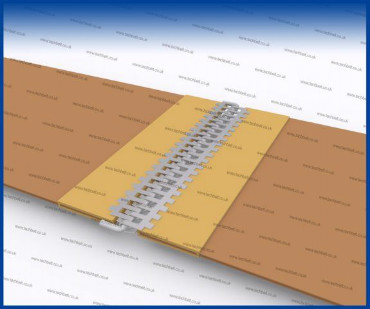

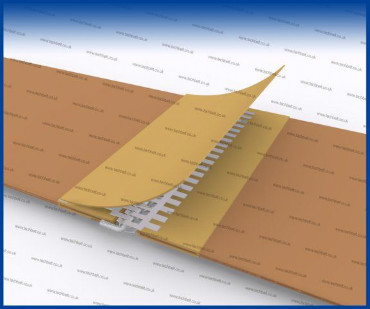

Alligator Belt Joints are stainless steel metallic fasteners with a tie bar across the back preventing any individual pieces coming away and potentially falling in to food products. These allow belts to easily to fitted and removed from conveyors.

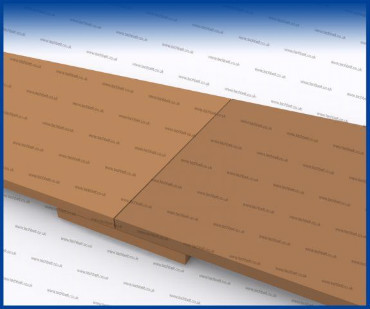

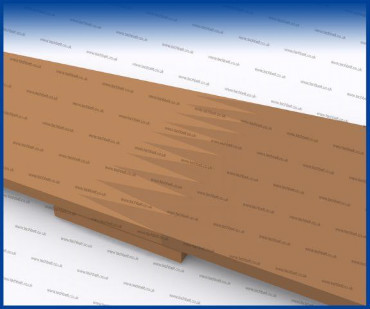

Butt Belt Joints tend to be manufactured prior to fitting on the machine and are manufactured using a strap on the underside to offer additional strength. This method is a simple but very effective on making a belt endless.

Castellated Belt Joints tend to be manufactured prior to fitting on the machine and are manufactured using a strap on the underside to offer additional strength. This method is a simple but very effective on making a belt endless.

Clipper Joints are very similar to Alligator types but tend to be smaller and more light weight. These allow the belt to be fitted and removed with ease.

Cover Belt Joints - Covers can be applied after joints have been fitted to act a barrier between the metallic surface of the joint and the product being conveyed.

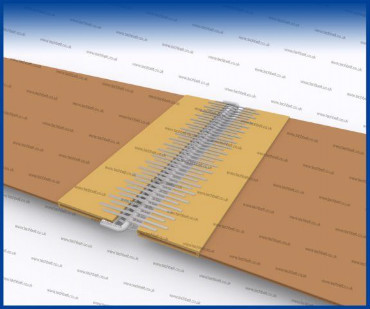

Finger Belt Joints - Finger joints are manufactured in a similar way to butt types but offer less stress on the joint and the jointed are is spread.

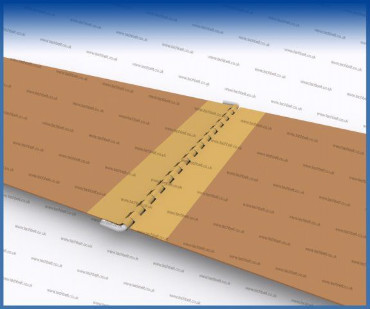

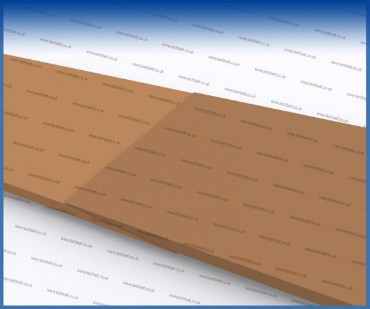

Scarfed Belt Joints - A scarf joint is similar the overlap butt offer a smooth transition for the product to run offering no lip for products to catch on.

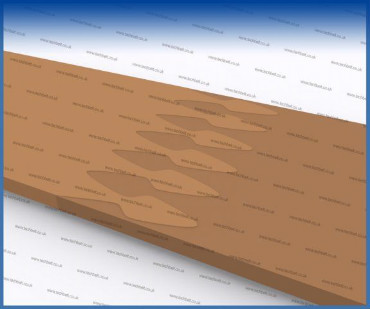

Spade Belt Joints - The spade offers the same benefits as a finger joint but can sometimes be more effective and there is no sharp tips the joint that may begin to lift over time.